jaw crusher types and functions

Jaw Crusher - ScienceDirect

2016年1月1日 Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, Nordberg () and others. The crusher is the C 200

What Is A Jaw Crusher - MEKA

Tertiary Crushing. This is the third stage of crushing. The size, which is around 50–80 mm, of the ore or rock from the secondary crushing process is reduced to between 5 and 12

What Are Jaw Crushers and How Do They

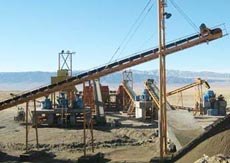

2019年3月28日 March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks.

sbm/sbm jaw crusher types and functions.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Jaw crusher: types, principle and applications ResearchGate

TYPES OF JAW CRUSHERS. Blake jaw crusher: In the Blake or jaw crusher the moveable jaw is pivoted at top. The greatest amount of motion is at the bottom which means it has

Characteristics and Comparison of Four Types of Jaw

2023年2月15日 Depending on different ways of moving, jaw crushers are divided into four types: Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw

Jaw crusher uses and functions-SBM Industrial Technology

2019年9月12日 The jaw crusher is very powerful. It needs to carry out all-round inspection and replace worn parts during overhaul. The general overhaul period is 1-2 years. In

Different Types of Jaw Crusher - sanmechina

2022年12月12日 Jaw crusher is a type of rock crusher. ... Though they do the same function in crushing rocks, the structures of the two types are different. The double-toggle

Understanding Jaw Crusher Parts and Their Functions

2023年2月23日 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher

Crusher - an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

Jaw Crushers McLanahan

On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double roll spherical roller bearings. The swing jaw undergoes two types of motion: one is a swing motion toward the opposite chamber side (called a stationary jaw die due to the action of a toggle plate), and the second is a ...

Gyratory Crusher - an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4). A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 4.4(a) ) and it is the most widely used in primary crushing stages ( Behera ...

(PDF) DESIGN AND OPERATIONS CHALLENGES

2017年6月30日 power consumed is a function of stroke, crushing ... that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jaw-type crusher shaft. The ...

Jaw crusher: types, principle and applications ResearchGate

TYPES OF JAW CRUSHERS. Blake jaw crusher: In the Blake or jaw crusher the moveable jaw is pivoted at top. The greatest amount of motion is at the bottom which means it has the little tendency to ...

sbm/sbm jaw crusher types and functions.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Characteristics and Comparison of Four Types of Jaw

2023年2月15日 Depending on different ways of moving, jaw crushers are divided into four types: Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw crusher. Blake jaw crusher There are two jaws in a blake jaw crusher, one is stationary and vertical, the other is movable and swing. The swing jaw reciprocates in a horizontal

Different Types of Jaw Crusher - sanmechina

2022年12月12日 Jaw crusher is a type of rock crusher. ... Though they do the same function in crushing rocks, the structures of the two types are different. The double-toggle jaw crusher consists of a swing jaw, a stationary jaw, an offset eccentric shaft, a pivot point and a double set of toggles. On the contrary, the overhead eccentric model contains a ...

Function Of Toggle Plate In Jaw Crusher Crusher Toggle

2023年2月16日 The main function of the toggle plate is to transmit the crushing force and absorb the reaction force generated during the crushing process. When the movable jaw moves down, the toggle plate compresses, and when the movable jaw moves up, the toggle plate expands. This movement creates a rocking motion, which helps to break up the

Cone Crusher - an overview ScienceDirect Topics

Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates.

Jaw Crushers McLanahan

On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double roll spherical roller bearings. The swing jaw undergoes two types of motion: one is a swing motion toward the opposite chamber side (called a stationary jaw die due to the action of a toggle plate), and the second is a ...

Cone Crusher - an overview ScienceDirect Topics

Figure 8.1 shows two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates.

Gyratory Crusher - an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4). A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 4.4(a) ) and it is the most widely used in primary crushing stages ( Behera ...

(PDF) DESIGN AND OPERATIONS CHALLENGES

2017年6月30日 power consumed is a function of stroke, crushing ... that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jaw-type crusher shaft. The ...

MC 110i EVO2 Mobile jaw crushers Kleemann - Wirtgen

Simple transport thanks to hydraulic functions (e.g. side discharge conveyor, crusher discharge conveyor) and a transport height of 3,400 mm; ... Single toggle jaw crusher type STR110-070 Crusher gap adjustment Fully hydraulic Gap width max. 7 in Gap width min. 1.2 in. Crushing capacity.

Different Types of Jaw Crusher - sanmechina

2022年12月12日 Jaw crusher is a type of rock crusher. ... Though they do the same function in crushing rocks, the structures of the two types are different. The double-toggle jaw crusher consists of a swing jaw, a stationary jaw, an offset eccentric shaft, a pivot point and a double set of toggles. On the contrary, the overhead eccentric model contains a ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Jaw Crusher Functions Crusher Mills, Cone Crusher, Jaw

Jaw crusher is one of the most popular stone-crushing equipments in the world, and improve the function of products continuously to meet the customer’s . Chapter 4. Jaw Crusher – #2fishygirl on Scribd Scribd. Jaw Crusher – Free download as PDF File (.pdf), Text File . Broman gives this critical speed as a function of crusher ...

Selecting the Right Crushing Equipment Agg-Net

2015年10月28日 The moving jaw plate is mounted on the pitman, which is given a reciprocating motion. Crushing takes place when the pitman moves toward the stationary jaw. There are two main types of jaw crushers – single toggle and double toggle. The single-toggle jaw crusher features a pitman mounted on an eccentric shaft at the top.

>> Next: Trituradora De Carbonato De Calcio En Mexico

Artículos Relacionados

- trituradora de impacto pequena roca

- en trituradora de argelia sur

- moinho triturador de ossos modelo sbm

- trituradora proyeccion trituradora

- que tipo de carbon se usa para hacer cemento

- moinho mandibula tonelada hora

- mineral de las minas de oro wow

- what equipment is used to process kaolin

- trituradoras de concreto de impacto primario corea

- el tamano de la amoladora de la mandibula

- mobile health screening services

- india trituradora mvil

- cuchillas industriales

- molienda proceso de la maquina giratoria

- renio circuito de chancado

- la eficiencia chancadora de cono zaonee

- venda de prensa vulcanizadora

- máquina de molienda de alimentos fabricantes alemania

- molibdeno procesamiento de la mineria

- chancadora de priedas

- precio de trituradoras de piedra en colombia

- trituradoras de piedra para la venta en colombia

- sketsa gambar pengayak pasir

- trituradora de arena movil

- la inversión minera en tanzania

- small scale mining in ghana

- mineral de hierro hematita separa Feb

- Piedra Caliza Compra

- de la empresa trituradora de SKD furlan

- molino de polvo raymond